Description

With development of solar technology,the changes for solar technology is Perc,N-Topcon,BC,HJT and Perovskite.

Compared with Perc,N-Topcon,Perovskite has higher efficiency,while it is sill in early stage about stability.

In China,99% of Perovskite solar panel is based on butyl rubber,soalr laminator is important machine for Perovskite research and trail production line.

The principle of solar cell laminator is to exert a certain pressure on the surface of each layer of material in the component,and press these substances tightly together under the state of heating.It is an important equipment for photovoltaic module manufacturing.

|

Model |

AZ-0404 | Laminate Length * Width | 400mm x400mm

|

|

Dimension |

900×950×1100mm | Weight |

500kg

|

|

Power supply |

380V 3 phase | Peak power |

5Kw

|

|

Pumping speed |

8L/S | Work power |

3Kw

|

|

Control mode |

Automatic/ Manual | Ultimate vacuum |

20 Pa

|

|

Heating mode |

Electrical heating system | Temperature control mode |

PID Control |

|

Maximum temperature |

180℃ | Temperature uniformity |

±3℃ Multi-point temperature control

|

|

Work temperature |

100℃~160℃ | Controllable temperature precise |

≤±3℃ (at the regulated set temperature value

|

|

Unevenness of the worktable |

Unevenness≤300 μm/m² | Air discharge speed |

Can adjust continuously within 0~50L/S

|

|

Press of compressed air |

0.5~0.8MPa | Laminate time |

about 15min. |

|

Pumping time |

4~5min | Compressed air speed |

1-8L/S |

|

Work vacuum degree |

80~20Pa | Ambient temperature |

0~50℃

|

|

Note: Customized specifications are available upon your requirements. |

|||

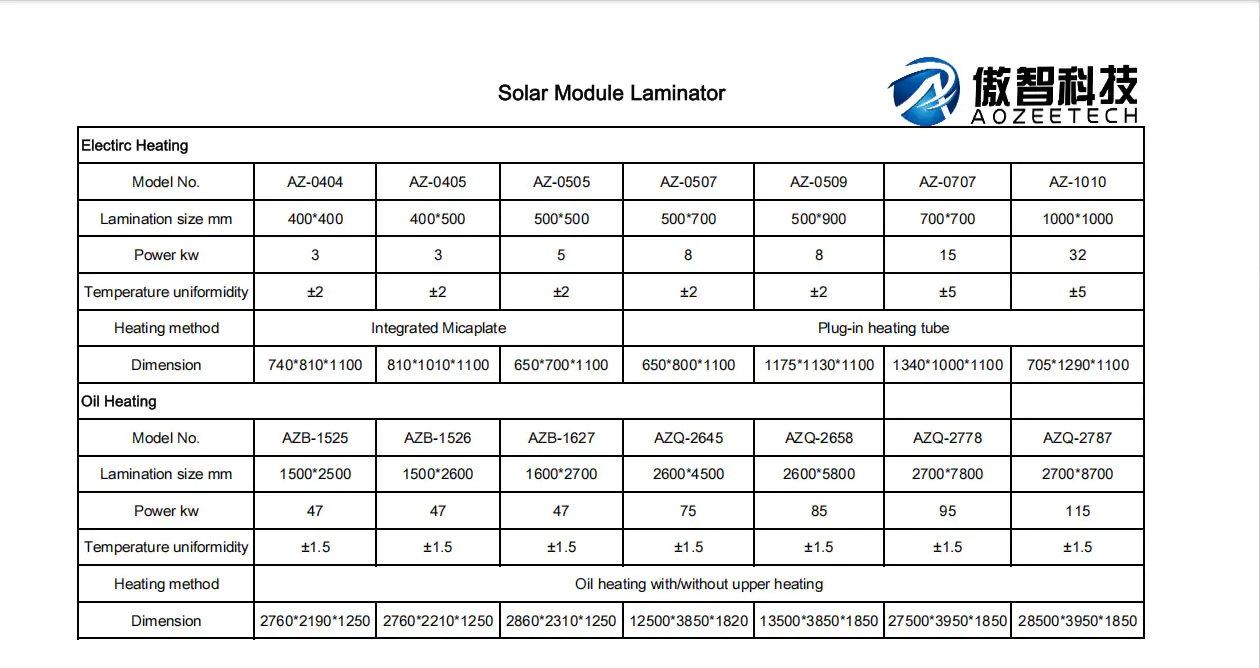

Various Solar Module Laminator Model No.

Reviews

There are no reviews yet.