Description

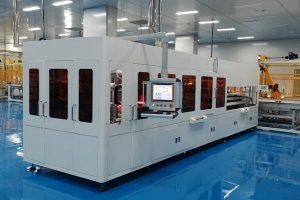

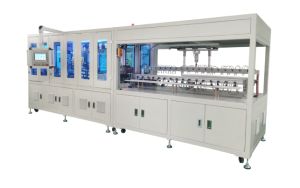

Solar Tabber&Stringer is a fully automatic machine used to older mono-Si or poly-Si cells into a stringer.

2400-2600cell/hour is higher speed compared 1300cell/hour,it meet 50MW solar panel production.

With CCD inspection and robotic loading system,connects automatic lay up machines,it makes more automatic for your production line.

| Net capacity | 2400-2600 cells/hour |

| Cell size | 50-210*210mm |

| Cell thickness | 160um~300um |

| Busbar | 6BB 9BB 12BB 13BB changeover time 0.5H(feature) |

| Ribbon width | 0.6mm-1.5mm |

| Busbar thickness | 0.15-0.21mm |

| Ribbon position | Less than 0.1mm shift |

| Flux coating | Sunk auto coating flux |

| Soldering method | Infrared heating |

| Breakage rate | ≤0.1%(A Grade Solar Cell) |

| String length | 2300mm(2-12pcs Full 182mm) |

| Length tolerance | ±0.5mm |

| Straightness tolerance | ±0.5mm |

| Cell gap | 0.8-30mm(adjustable) |

| Cell position | Robotic + CCD Position |

| Cell string transmission | Teflon transmitation belt, driven by servo motor |

| Cell defect detection type | crack/cold welding/cell reveral /surface stain by Eye Visual |

| Layup method | Automatic layup/manual layup |

| HMI | Integrated touch screen IPC with cantilever operation box and English/Chinese interface |

| Uptime | ≥95% |

| Electric system | PLC plus servo system |

| Power | 50-60Hz/AC380V / 3 phase 5 lines |

| CDA pressure | 06-0.8MPa |

| CDA consumption | 500 liters / min |

| Dimension | 5800*2000*2050mm(L*W*H) |

| Weight | 3000kg |

Reviews

There are no reviews yet.